Your Trusted Heat Sink Manufacturer with 20+ Years Experience

Industrial-Grade Heat Sinks, Delivered Globally.

Flexible Batch Quantities and Cost Effective.

ISO-Certified Manufacturer

XINXIANG is an ISO:9001 certified heatsink manufacturer. From material to finish, we try to meet the highest standards in thermal engineering.

Existing Tooling Inventory

We have a wide range of standard molds, especially for extruded heat sinks. Pre-made solutions for other custom heatsinks are also available.

Cost Effective, Fast Delivery

With years of experience in thermal industry, we will support you to keep your heat sink projects within budget and make it faster.

Trusted by hundreds global clients and organizations of all sizes

From Design to Delivery: Your Cooling Partner

XINXIANG is a professional heat sink manufacturer with over 20 years of industry experience. We manufacture both copper and aluminum heat sinks that include extruded heatsinks, skived fin heatsinks, bonded heatsinks, forged heatsinks, die casting heat sinks and heat pipe heat sinks. Liquid cold plates are also one of our main product lines that include aluminum and copper cooling plates.

Our custom and standard heat sinks are suitable for a wide range of applications. With deep manufacturing expertise, strict quality control and commitment to continuous improvement, we aim to deliver high-quality thermal solutions with reliable, cost-effective heat sink products that meet the needs of our customers.

A Leading Heat Sink Manufacturer

- Wide Range of Existing Molds.

- Precision Manufacturing

- Certified Quality, Industrial-Grade Results.

- Globally Delivered

Our Products

Our extensive manufacturing capabilities include extrusion, skiving fin cutting, stamping, die casting, cnc machining and assembly, that allow us to produce an extensive series of standard and customized heatsinks to meet the diverse needs of our clients.

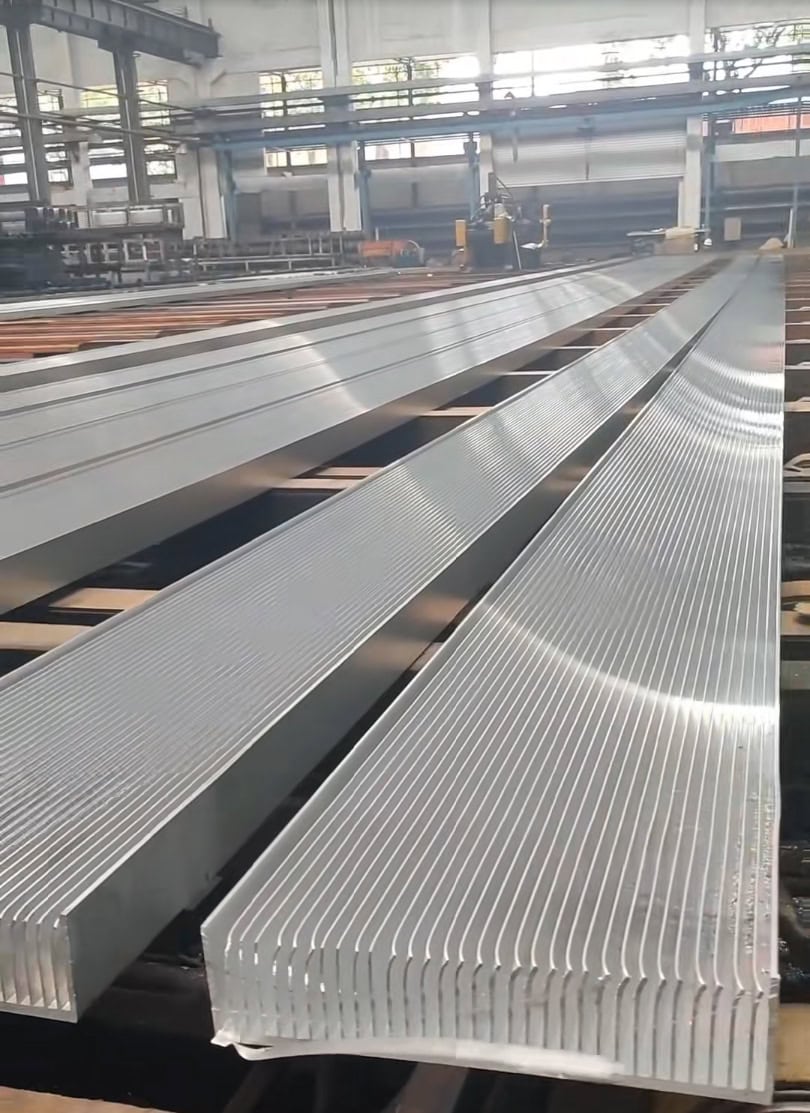

Extruded Heat Sink

Skived Heat Sink

Skiving from a solid metal block creates a one-piece, high-density fin array ideal for high-power or space-constrained cooling.Bonded Fin Heat Sink

Brazed or epoxied fins on a grooved base allow taller, denser fin structures, delivering superior cooling for high-power electronics.Heat Pipe Heat Sink

Sealed heat pipes use phase-change to move heat rapidly from hotspots into a fin stack, delivering high thermal performance in thin, space-constrained or uneven-load electronics.Forged Heat Sink

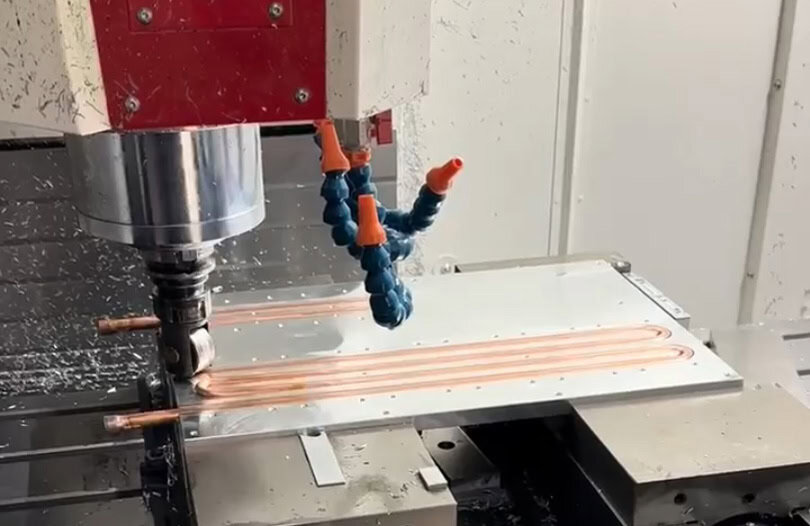

High-pressure forging yields a robust one-piece heat sink with dense pin fins for optimal cooling in compact, high-vibration applications.Liquid Cold Plate

Integrated liquid channels in a metal plate deliver superior heat removal for high-power applications beyond the capabilities of air cooling.Materials We Use

At XINXIANG, we manufacture heat sinks using both aluminum and copper to meet different thermal, structural, and budget requirements.

Aluminum is lightweight, corrosion-resistant, and cost-effective, making it ideal for most general-purpose cooling needs. Copper offers superior thermal conductivity and is preferred in high-performance or space-constrained applications.

We select the right material based on your project’s performance, environment, and cost priorities — ensuring optimal thermal management every time.

Copper for Peak Thermal Performance

Copper heat sink offers the highest thermal conductivity, ideal for compact, high-power applications where heat transfer efficiency is critical.

Aluminum for Lightweight Efficiency

Aluminum heat sink provides a perfect balance of conductivity, weight, and cost — widely used in extrusion and large-scale production.

Material Flexibility for Custom Solutions

Copper or aluminum — we choose the right metal for your budget, design needs, and thermal requirements.

Sustainable Metals. Greener Cooling.

Both aluminum and copper are fully recyclable, supporting eco-friendly production and reducing environmental impact in thermal management solutions.

Multiple Processes to Deliver Thermal Products

Within our 50,000 square foot production facility, we are equipped with a complete range of heat sink manufacturing machinery.

Our in-house processes include extruding aluminum profiles, skiving, metal stamping, die casting, CNC machining, and mechanical assembly. This extensive capability allows us to handle everything from high-volume standard profiles to complex custom thermal components. Whether you require lightweight extruded heat sinks, high-density skived fins, precision-stamped bases, or fully assembled liquid cold plates, we have the technology and expertise to deliver.

Our integrated workflow ensures fast production, consistent quality, and cost-effective results — all under one roof. With flexible tooling and a highly experienced team, we’re ready to support projects across multiple industries, from industrial automation to telecom and beyond.

Industries We Serve & Applications

Amplifiers

Heatsinks are critical in high‐power amplifiers, dissipating heat from output transistors to prevent overheating and maintain performance reliability.LED Lighting

High-power LED lighting systems rely on heat sinks to dissipate heat away from LED modules, which extends the LEDs’ lifespan and maintains consistent brightness.Motor Drives

Heat sinks dissipate thermal energy from power modules in motor drives, supporting long-term performance in industrial automation systems.Electronics

Electronic devices - from consumer gadgets to industrial controllers—use heat sinks to cool chips and power components, ensuring reliable operation and long device life.Finned Enclosures

Finned extruded aluminum enclosures provide passive heat dissipation and IP-rated protection for outdoor electronics, power supplies, and industrial controls.Liquid Cold Plate

Circulates coolant through internal channels to remove high heat loads in EVs, lasers, power inverters, and high-density electronics.Active Heat Sink

Uses integrated fans to enhance airflow, improving thermal performance for CPUs, GPUs, and other high-power electronic components.What Our Clients Say

“We needed custom heat sinks for a new project, and XINXIANG delivered exactly what we had in mind. Fast quoting, good pricing, and really nice people to work with.”

“They had plenty of existing molds for finned heatsinks to choose from. We found a match fast, saved time on tooling, and went straight into production without delays.”

Their team is professional and quick to respond. They helped us solve some tricky thermal issues, and the heat sinks they delivered worked perfectly with our designs.

“What I like most is how easy it is to get answers. They’re fast, professional, and really understand what engineers like us need in real-world applications.”

How long does it take to get a quote?

Usually within 24 hours. Just send us your drawing or basic specs — the more info you share, the faster we can quote accurately.

Do you have standard heat sink sizes, or are they all custom?

Absolutely. We offer both standard and fully custom heat sinks. If you’ve got a drawing, great — if not, share us info of your project, we’ll help you find a fit.

What materials do you use for heat sinks?

Mostly aluminum and copper. We’ll help you pick the right one based on performance, weight, and cost.

Can you help with thermal design or selection?

Sure thing. Our team can review your specs and suggest suitable materials, fin types, or cooling methods based on your application.

Do you support small volume orders or prototypes?

We do. Whether you need 10 pieces or 10,000, we’re flexible. We also support prototyping for new designs. Send us your design and required quantity, we will receive a quote from us.

What is your production lead time?

We’ve got a large inventory of existing molds. That means we can sometimes skip the tooling stage and jump straight into production. For that it takes us 1 to 4 weeks depending on the details of your order.

For an order that uses custom heat sink mould, the tool development and submitting sample for approval is usually required. We can also work on that quickly.

How do you pack the heat sinks?

We will use the most suitable packing method to protect the goods during transportation, that may include cartons, pallets or crates.

If you have specified demand on package, we can do it as per your requirements.

Can you do door-to-door shipping?

Yes, we can. We work with several reliable freight forwarders and can arrange door-to-door shipping to most countries — just let us know your delivery address.

We can also use your freight forwarder if you have one.